Hi folks, i just wanted to share with you some progress pics on the trim for the blade gauntlet. Here they are:

This is what i have started with so far for the bottom gauntlet piece. I used fosshape for the trim here.

Side view of the fosshape trim on the top portion of the gauntlet and blade.

Side view showcasing the trim across the entire blade gauntlet and me once again wearing my gauntlet finger, god i love those lol. As you can see i ma using fosshape across the entire gauntlet for the trim, i find it is an excellent material to use for it when adding trim to armor that has multiple curves, and you want the trim to have a thickness to it.

What i have found that is interesting is there is a fabric glue i love to use called "fabric tac" for those of us sewing challenged this stuff is a god send. It even survives the washer and dryer! I took a chance and tried it out on the fosshape and it performs beautifully, just as if i have sewn the edges the "fabric tac" works in the same fashion, allowing me to heat set the fosshape. I even tried it here on the gauntlet, gluing the fosshape to the gauntlet- then once the glue dried (which was under like 4 min) i lightly heat set it with a heat gun. As you can see it worked out beautifully.

I intend on using this technique alot for the legs and feet portions of the armor.

Friday, March 30, 2012

Thursday, March 29, 2012

Hello folks, I have had a busy day here at my Creation table. I have just about completed the base assembly for the right Blade gauntlet, here are the progress pics on it.

This is the top and bottom gauntlet fitted and shaped just right.

How it looks on me from both the outside and inside view.

Now i am bonding the blade to the gauntlet with strips of wonderflex.

Myself wearing it, believe it or not this feels so lightweight on my arm. Next step is detailing it up then off to make the other Blade gauntlet.

This is the top and bottom gauntlet fitted and shaped just right.

How it looks on me from both the outside and inside view.

Now i am bonding the blade to the gauntlet with strips of wonderflex.

Myself wearing it, believe it or not this feels so lightweight on my arm. Next step is detailing it up then off to make the other Blade gauntlet.

Wednesday, March 28, 2012

Hi folks, i got another shipment of Wondeflex in so i jumped right back into my costume design. And what I decided to do a bit of work on is my gauntlet forearms, here are my beginning pics of it:

Here I am bending the wonderflex around me forearm for the perfect fit.

As you can see i am wearing a long john shirt, to protect me from the heat in the forearm piece as is bends to the shape of my arm. ( and yes material does stick to wonderflex so i had to make sure to pull it off my thermal shirt a few times as it cooled, you can also just put a bit of wax paper over your arm too to avoid having to remove it as it cools).

Ok this part of the gauntlet is about ready now to test it with the gauntlet fingers.

Ok the test is looking good i will have great movement between the forearm piece and fingers.

Here I am bending the wonderflex around me forearm for the perfect fit.

As you can see i am wearing a long john shirt, to protect me from the heat in the forearm piece as is bends to the shape of my arm. ( and yes material does stick to wonderflex so i had to make sure to pull it off my thermal shirt a few times as it cooled, you can also just put a bit of wax paper over your arm too to avoid having to remove it as it cools).

Ok this part of the gauntlet is about ready now to test it with the gauntlet fingers.

Ok the test is looking good i will have great movement between the forearm piece and fingers.

Friday, March 23, 2012

Evening folks, I finished the fingers for the right hand! Here are the progress pics of them.

I added a little padding inside for a more snug and comfy fit.

Fingers closed.

Underside of the fingers open.

Articulation and the ability to grab smooth objects check! Next step is to use friendly plastic over all the black lines i drew on the fingers, then a little smooth cast over all the fingers for added durability, then of to do the left hand!

I added a little padding inside for a more snug and comfy fit.

Fingers closed.

Underside of the fingers open.

Articulation and the ability to grab smooth objects check! Next step is to use friendly plastic over all the black lines i drew on the fingers, then a little smooth cast over all the fingers for added durability, then of to do the left hand!

Wednesday, March 21, 2012

Hello fellow armor lovers, i decided to jump to a totally different part of the armor suit today, and start working on the gantlet fingers! Here are the progress pics on those:

Pictured here is the thumb index finger and the middle finger. Basically where you see black lines at i will be using friendly plastic in those spots to give it a bit more dimension.

This is me wearing it, it feels real comfy after i put some fosshape inside to act as padding around the finger tips.

Close up shot of the fingers.

Close up shot of the thumb.

This is a shot of me closing my hand to test the fingers to make sure it bends properly and with ease.

Pictured here is the thumb index finger and the middle finger. Basically where you see black lines at i will be using friendly plastic in those spots to give it a bit more dimension.

This is me wearing it, it feels real comfy after i put some fosshape inside to act as padding around the finger tips.

Close up shot of the fingers.

Close up shot of the thumb.

This is a shot of me closing my hand to test the fingers to make sure it bends properly and with ease.

Monday, March 19, 2012

Hi folks, i am back again with another update.

This time i finished one pauldron to the point where i just need to sharpen up my edges and smooth it out with friendly plastic, then coat it with about 4-5 layers of smooth cast, then finally airbrush it. So that said i figured why not take pics of it with the helm on, tell me what you think!

Front view

Three quarter view

Side view

Back view (after this pic i also adjusted the trim on the right side to be more along the base of the horn as the left side is)

What do you guys think?

This time i finished one pauldron to the point where i just need to sharpen up my edges and smooth it out with friendly plastic, then coat it with about 4-5 layers of smooth cast, then finally airbrush it. So that said i figured why not take pics of it with the helm on, tell me what you think!

Front view

Three quarter view

Side view

Back view (after this pic i also adjusted the trim on the right side to be more along the base of the horn as the left side is)

What do you guys think?

Sunday, March 18, 2012

Hi folks, since now i am in final touches mode on the helm before the paint job, i wanted to try something a bit different. I originally was going to use just friendly plastic for the trim. But considering the amount of it that i will use costume wide i decided to try to be a bit conservative with it. So I decided to use Fosshape for the base of the trim, then i will use friendly plastic over it, this way i do not need to build up several layers to get the height i need.

It will now just need one layer of friendly plastic, and that will be to layer over the top of the fosshape and blend the side of the trim to the helm.

Basically i run the heat gun over the section of wonderflex that i intend on attaching the fosshape to. Once it is warm enough i lay the fosshape over it and press firmly.

The top portion is set, now for the bottom.

Front trim using fosshape is done. Now just need to work the friendly plastic magic onto it then the smooth cast and i will be ready to airbrush some magic on it.

It will now just need one layer of friendly plastic, and that will be to layer over the top of the fosshape and blend the side of the trim to the helm.

Basically i run the heat gun over the section of wonderflex that i intend on attaching the fosshape to. Once it is warm enough i lay the fosshape over it and press firmly.

The top portion is set, now for the bottom.

Front trim using fosshape is done. Now just need to work the friendly plastic magic onto it then the smooth cast and i will be ready to airbrush some magic on it.

Friday, March 16, 2012

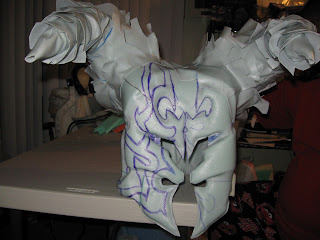

Hi folks, time to show you the next piece of the armor I have been working on. The helmet! I have attached the horns to it and begun working on the face. Here are my progress shots on it:

I have already completed one side of the helm so i am starting on the other and let you good folks see how i went about constructing it. In this pic since i already had the base structure of the helm covered with wonderflex, i simply cut out the shape i needed in foam, then took the heat gun and heated up the section of the helm i wanted to work with, and stuck the foam directly to it.

As you can see the foam sticks to it perfectly, next i will cover it with a layer of wonderflex. The reason why i do this is 2 fold:

1) SAVES wonderflex ( you def want be frugal with your use of it, i try to use all my scrap pieces if at all possible)

2) I find when u are building up layers doing it this way allows for way more flexibility when u have to do bends like the one pictured here.

Here I am cutting out a piece of wonderflex to go over the cheek portion of the foam i just attached to the helmet.

Applying the heated up piece of wonderflex i just cut and attaching it to the cheek foam.

The Cheek is good to go. Now i just repeated the same process for the jaw bone section.

I cut out another section of wonderflex and heated it up and applied it over the piece of foam i adhered to the helmet.

Same procedure for the lower jaw.

Ok, now i need to do my trim outline for the plain side of the face. I intend on filling in those trim lines with friendly plastic to give it more dimension.

And here we go the front is almost done, next i need to add a bit of trim to the lower back of the helmet, that is shown in this next pic:

Adding the trim using the same method to conserve on wonderflex, one thing about doing armor this detailed is you run thru the stuff so fast.

Cutting the wonderflex into strips and applying each one at a time to ensure greater control and bend-ability of it.

Each section falling into place well.

Making sure the inside portion on the bottom trim is running flush along the inside of the helmet as well.

I have already completed one side of the helm so i am starting on the other and let you good folks see how i went about constructing it. In this pic since i already had the base structure of the helm covered with wonderflex, i simply cut out the shape i needed in foam, then took the heat gun and heated up the section of the helm i wanted to work with, and stuck the foam directly to it.

As you can see the foam sticks to it perfectly, next i will cover it with a layer of wonderflex. The reason why i do this is 2 fold:

1) SAVES wonderflex ( you def want be frugal with your use of it, i try to use all my scrap pieces if at all possible)

2) I find when u are building up layers doing it this way allows for way more flexibility when u have to do bends like the one pictured here.

Here I am cutting out a piece of wonderflex to go over the cheek portion of the foam i just attached to the helmet.

Applying the heated up piece of wonderflex i just cut and attaching it to the cheek foam.

The Cheek is good to go. Now i just repeated the same process for the jaw bone section.

I cut out another section of wonderflex and heated it up and applied it over the piece of foam i adhered to the helmet.

Same procedure for the lower jaw.

Ok, now i need to do my trim outline for the plain side of the face. I intend on filling in those trim lines with friendly plastic to give it more dimension.

And here we go the front is almost done, next i need to add a bit of trim to the lower back of the helmet, that is shown in this next pic:

Adding the trim using the same method to conserve on wonderflex, one thing about doing armor this detailed is you run thru the stuff so fast.

Cutting the wonderflex into strips and applying each one at a time to ensure greater control and bend-ability of it.

Each section falling into place well.

Making sure the inside portion on the bottom trim is running flush along the inside of the helmet as well.

Monday, March 12, 2012

Hello again folks, my horns are at the final touch up stage yay! here are the progress pics:

I affix the well to the helmet, then slide in the horn. Then i heat set the sides of the well to the horn, and add a few extra pieces of wonderflex to blend it in. i will show pieces of that process soon as well.

All ready for the detail process now with friendly plastic.

I went ahead and made what i call a well for the horn. What this does is allow me to anchor the horn to the helmet a lot more sturdier.

Subscribe to:

Posts (Atom)